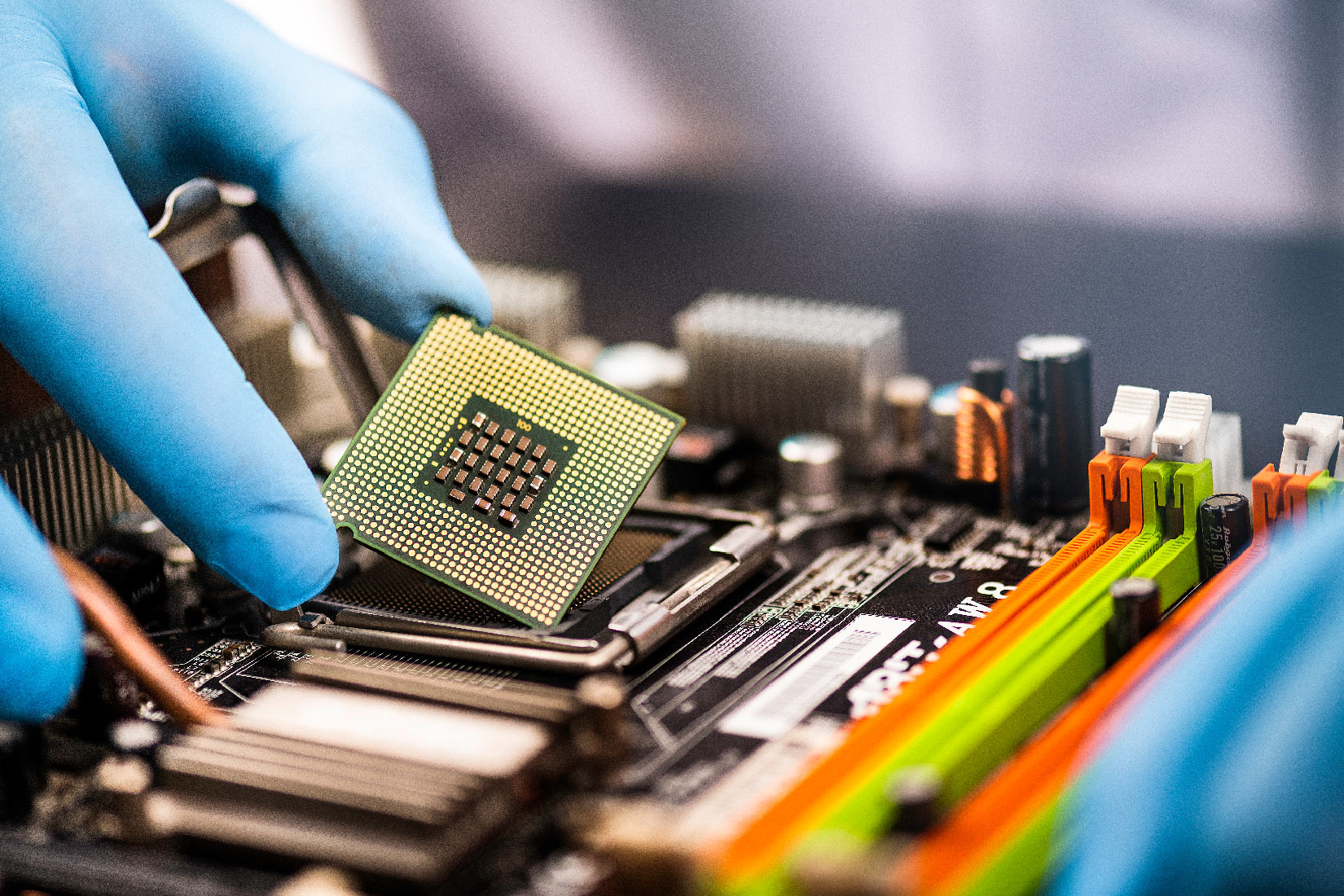

Ball Grid Arrays (BGAs) are the dominant method of connecting chips packaged in a variety of ways to the main board. Because BGA package technology is so widely used, BGA inspection is among the most common applications for acoustic microscopy. The Sonix ECHO platform is the ideal BGA inspection platform.

Sonix has extensive experience with BGA package technology, helping customers identify BGA defects such as moisture-induced cracking, delaminations, lid seal integrity, die attach and other defects in both plastic and metal BGA packages. That’s why so many manufacturers worldwide choose Sonix BGA inspection systems to identify and characterize defects.

BGA Defects Sonix Identifies:

© 2024 Sonix. All Rights Reserved.