The ECHO VS system adds our Image Enhancement Suite to the ECHO platform to provide industry-leading image quality and defect identification capabilities. It’s our most accurate ultrasonic NDT equipment for development labs and for production environments that require the highest precision. The Echo system can be fitted with an optional chuck for manual wafer inspection.

To identify the smallest and most subtle defects in leading-edge packaged microelectronic applications, ECHO VS includes standard features such as heated water for optimum acoustic coupling, Flexible TAMI for efficient capture of the most useful data, Waveform Averaging for an improved signal-to-noise ratio, ICEBERG for improved image quality and MFCI for enhanced image quality in the most demanding applications. ECHO VS is the ultimate ultrasonic NDT equipment for molded flip chip, CSP, MCM, stacked die, MUF and other advanced packaging technologies.

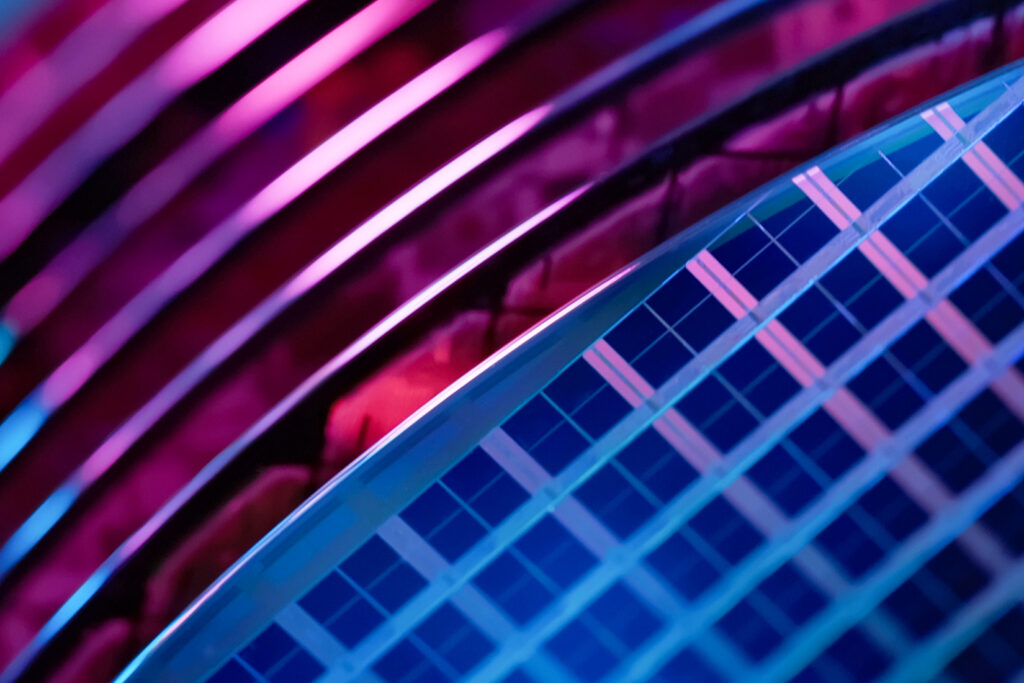

Sonix offers powerful wafer software tools to enhance bonded wafer imaging, accelerate production and adapt AutoWafer and AutoWafer Pro to our customers’ specific requirements.

Sonix S-series ultrasonic NDT transducers are designed in-house to meet the demanding nondestructive testing requirements of semiconductor manufacturing. We offer the collaborative expertise to help customers choose the best ultrasonic NDT transducer for their application.

Sonix has the expertise to help you image specific interfaces of interest within the chip scale package, efficiently gathering the most useful data so you can maintain the multi-chip package throughput you need.

Provide a sample of your product. Sonix will provide you with an in-depth analysis report and help you develop an inspection solution designed to integrate into your process.

© 2025 Sonix. All Rights Reserved.