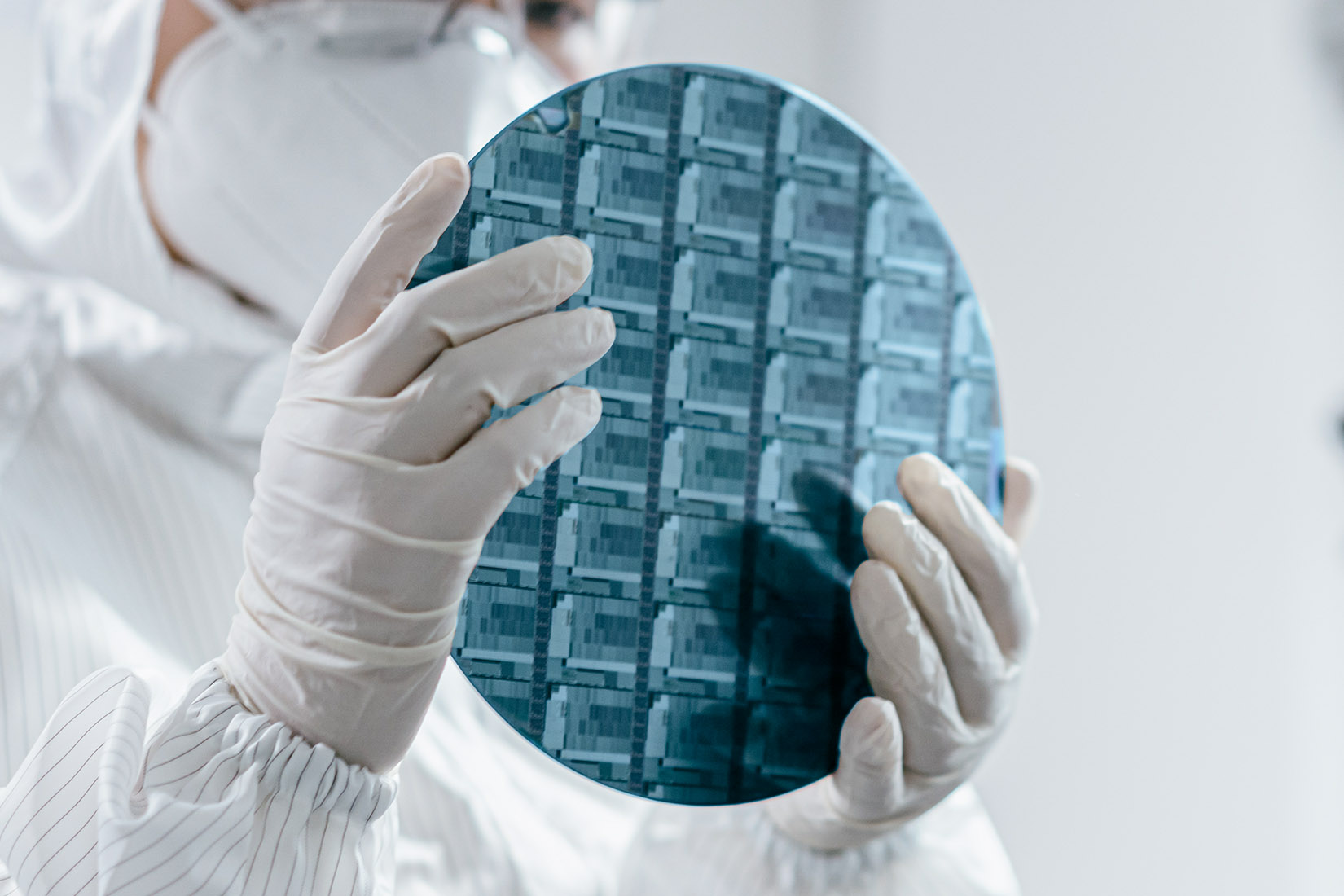

Sonix provides manual and automated wafer inspection and metrology systems for wafers ranging from 100mm to 300mm, with extensive analysis capabilities at both the wafer and device level. These industry-leading automated wafer inspection systems are used by the world’s top manufacturers to ensure quality from development through production.

© 2024 Sonix. All Rights Reserved.